Contents

Plaster of walls under wall-paper (as well as under paint) has to provide creation of a surface of the increased flatness and smoothness. Especially it is important if in the apartment finishing is planned by photowall-paper.

On a surface microwaves and also granularity more than 0.3 mm, differently all this are not admissible, jarring on a thin paper cloth, will make careless appearance of wall-paper.

Therefore important not only to solve, than to plaster walls (what structure more preferable), but also it is correct to execute all sequence of performance of work on each of technological stages.

Than to plaster walls under wall-paper

As rooms of the apartment, a condition in them, material of the basis and its state are various, it is necessary to make the choice of plaster not only taking into account budget opportunities. Also what technology will be applied is considered.

For example, at the mechanized plastering of the big areas special structures are required. For alignment of walls manually use plaster mixes or cement structures more often, is more rare – limy.

Cement and sand plasters apply together with hard putties as to achieve the necessary quality of a surface of solutions cement and sand – a difficult task even to professionals.

If walls are put from gas-concrete blocks, tongue-and-groove plates, covered with sheets of gypsum cardboard, choose plaster plaster under wall-paper of any thickness.

The reasons taken into consideration:

- The covering turns out the easy, not loading the basis weight.

- Plaster at a skhvatyvaniye behaves in relation to the basis more gently, than cement. Plaster mix does not shrink, and cement mortar is pulled together, there is internal tension which is transferred to material of walls.

- The plaster covering has the properties close to basis material, at operation behaves also as walls during fluctuations of temperatures and humidity.

- The covering from plaster, thanks to a set of a small time, does not block breath of wall materials.

- It is better "not to push together plaster with cement foreheads" because they clash on "the chemical field". In use, at direct contact, there is a destruction of crystals of cement the substances emitted by plaster over time. There is a stratification, falling away of pieces of a covering. The solution of the problem of the neighbourhood requires a dividing layer.

- Such choice corresponds to the rule: material of a covering should not be stronger than basis material.

For premises, for example, bedrooms, the living room and the nursery plaster plaster – the best material. Where the person needs favorable a microclimate, address the plaster participating in regulation of humidity, softening temperature jumps, better muffling noise.

For non-residential premises with concrete walls for reasons of durability, moisture resistance, availability of cement and other components (if the structure is trained independently), the smaller price – choose plaster with cement knitting.

Brick surfaces "accept" any structures. However, if the brick is fragile, begins to crumble, it is more rational to choose for walls mixes with plaster knitting. For walls from a tree use clay or plaster plasters.

Limy plasters apply less often now.

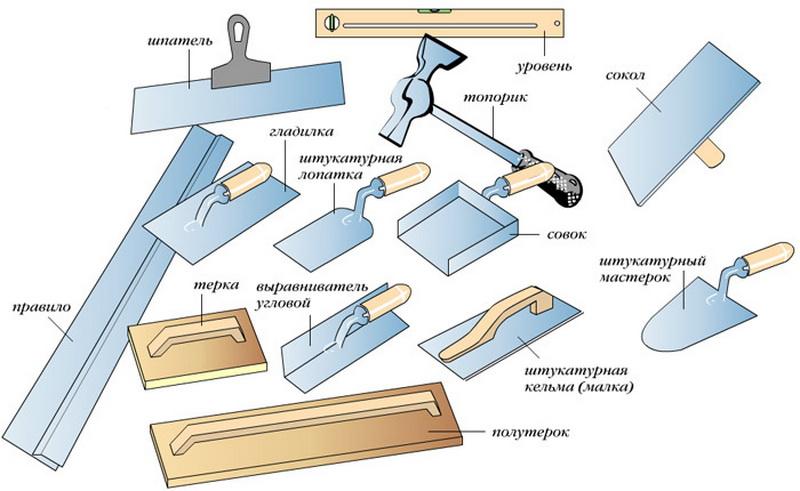

Tools and auxiliary devices

The "correct" tools facilitate performance of the demanding physical efforts of preparatory and also plaster operations. Also small-scale mechanization used for preparation of solution, putting mix will be not superfluous.

For preparation of solution are necessary:

- capacities (measured, under solution);

- construction mixer;

- trowel or pallet.

For preparation, drawing:

- falcon (use more often than the master);

- trowel (with a shovel from stainless steel);

- different sizes pallets;

- rule;

- polutyora, graters;

- brushes;

- ladle plaster (masters for performance of an obryzg usually use);

- the roller (for priming);

- level;

- cord;

- roulette;

- painting adhesive tape (for protection of not plastered surfaces);

- clean rags.

Except dry plaster mixes (CC), fillings, primers prepare also (on requirement) corners, mayachny profiles, an armosetka.

Criteria for selection of technology of plastering

Different types of plaster, even executed by professionals, on quality of roughness differ:

- Cement and sand solutions do not suit for gluing of paper wall-paper as even the qualitative zatirka leaves strong roughness. Under thin wall-paper smoothing is required by a shpaklevaniye.

- The limy plaster executed with a nakryvka allows to paste wall-paper with a reinforced cloth and also duplex.

- The quality surface can achieve processing of plaster plaster even without shpaklevaniye that is necessary for photowall-paper, silk-screen printing.

Several types of wall-paper do not demand so ideal surfaces:

- vinyl;

- steklooboyny;

- flizelinovy cloths;

- liquid wall-paper.

- Flizelinovy wall-paper

The first three views – because of cloth thickness, the last – features of material and also technology of its drawing.

According to Construction Norms and Regulations (the updated version of norms 3.04.01-87) the quality of the surface intended under bonding of wall-paper can be two categories:

- K3 – under panels on a paper or flizelinovy basis is admissible presence of traces of processing by abrasive materials up to 0.3 mm in depth.

- K4 – under the glossy and metallized thinnest wallpaper cloths is not allowed any scratches, at side illumination of shadows should not be.

Order of plaster of walls under wall-paper

The order which is followed when performing plaster of walls under wall-paper is similar to the sequence of stages of plastering under other types of finishing finishing. Unless, drawing a waterproofing is excluded.

Installation of beacons and reinforcing are not always also necessary. The last is carried out at a thickness of a plaster layer – more than 15 mm (for plaster), more than 40 mm (for cement).

Sequence of stages:

- preparation of the basis (for increase in adhesion, durability, prevention of a vystupaniye of spots);

- installation of beacons;

- solution zatvoreniye;

- drawing (consecutive) layers of plaster mix;

- zatirka;

- removal of beacons;

- priming;

- shpaklevaniye;

- drying.

Preparation of walls

Before beginning to plaster walls under wall-paper, the surface is processed.

- If a wall new, then after survey it is cleaned from spots, metal speakers of a detail cut off or isolate.

- In a bricklaying embroider seams, deepening them on 1 cm.

- Repair cracks and vykola, cut down ledges.

- From concrete apply notches on a surface of walls.

- Delete the available dust from a surface.

- Ground.

- Wooden surfaces upholster with shingle laths.

- If it is required, to a wall fix a plaster grid.

- Dry up.

Carrying out these operations, try to obtain increase in adhesion of a surface and also undertake measures for protection of finishing against emergence of spots and defeat by microorganisms.

In case of repair of the walls having an old covering its survey, check of durability, removal of unusable layers, repair work are added to the beginning of the list.

Beacons

If the wall is filled up, or surface deviations from the plane more than 10 mm are observed, plaster alignment (draft plaster) by means of beacons is required. Mayachny profiles establish on level, creating the auxiliary vertical plane.

Distance between profiles – from meter and more (depends on experience of the plasterer and length of the rule). Views of beacons and also ways of their installation are different. The final geometry depends on the accuracy of installation of profiles.

Solution preparation

From what plaster is used under wall-paper, the way of preparation depends. Some types of structures have the short term of life, for example, plaster therefore dissolve mixes in the small portions. Long-living solutions can be prepared by parties more.

The sequence of mixing is also various. Plaster CC pour into juicy water. Cement and sand ready CC – also. If cement and sand mixture is made in a trough in certain proportions, mixing cement and sand independently, then before mix dry components then pour (gradually) in water.

For hashing use the mixer. The solution prepared in a trough is mixed a shovel. It is more rational to involve large volumes in a rastvoromeshalka.

Obryzg

The first of the put layers which is intended for creation of a "buffer" covering. It provides strong coupling of all plaster covering with the basis. In case of plaster plaster this layer is passed.

Limy and cement solutions for an obryzg do by less viscous, cover a wall a ladle or a trowel. The surface is not leveled, on the contrary, put for the best coupling horizontal grooves with a tool tip.

Nakryvka

After drawing (over an obryzg) and levelings by the rule of a layer of earth, give it time for a skhvatyvaniye. Then, having removed beacons, carry out a nakryvka (at plaster plaster this stage is passed). Solution for a nakryvka is done less zapesochenny and viscous, than dough for soil. Sand undertakes small fractions.

Layer which thickness no more than 5 mm, apply wide with spatula before soil dries. The limy and plaster nakryvka is suitable for soil on the basis of lime better.

Zatirka and steeling of walls

Nakryvka later there began the skhvatyvaniya, but before drying, rub clean, using graters. Before the beginning moisten with a maklovitsa (sprinkling) water a nakryvka surface. The tool is put flatwise, the zatirka is conducted round.

Over ledges pressing is strengthened, over hollows – weakened. For receiving more smooth surfaces after a circular zatirka rub clean in a razgonka. As a result solution lumps are removed, a time is filled, traces keep from the tool.

For giving of smoothness to plaster coverings use bespeschany solution. Plaster is dissolved on glue liquid. Apply by means of a gladilka on small (~ 0.5 sq.m) the site of a wall a zigzag, holding a gladilka shovel under 20-25 hail. to a wall.

Put with a trace still a layer and, without taking a break, smooth down "on sdir" a gladilka edge in the cross directions. Similarly, using limy and plaster weight without sand, it is possible to smooth down plaster on lime.

Steeling is applied to strengthen (to condense) layer top. Acrylic plasters at the same time find luster. Steeling by pallets or trowels with shovels is made of stainless steel, repeated carrying out the tool on plaster top with pressing.

Hard putty

If plaster of walls under wall-paper has no desirable degree of smoothness that more often happens to cement structures, the surface is puttied. Before putting hard putty the wall is grounded. For a shpaklevaniye producers release CC two types – basic and finishing (with fillers of an osobotonky grinding). It is also possible to get ready weight.

Apply spackling mix with spatula a thin layer (to 3 mm) strips with an overlap with overlapping of 6-8 cm. The recommended corner for the pallet – 45 lakes. In the first pass cause basic structure, in the second – finishing. The quality is controlled, lighting the plane with side light.

Plaster of walls after wall-paper

Over old wall-paper it is impossible to plaster as paper has no that durability, as plaster. The layer of old wall-paper should be removed completely. For what they are soaked and deleted with the pallet.

After removal of wall-paper the basis is examined. If under wall-paper a wall equal, old strong plaster strong keeps, its surface is prepared as it is described above.

That the apartment after the next repair long did not demand new, plaster of walls under wall-paper has to be executed by rules — at each stage the technology corresponding to type of the chosen plaster structure is observed.

(yet there are no estimates)

(yet there are no estimates)

What is the time plaster depending on a type of mix and material of the basis dries

What is the time plaster depending on a type of mix and material of the basis dries